"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

10/19/2015 at 06:28 ē Filed to: Spit6

10

10

24

24

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

10/19/2015 at 06:28 ē Filed to: Spit6 |  10 10

|  24 24 |

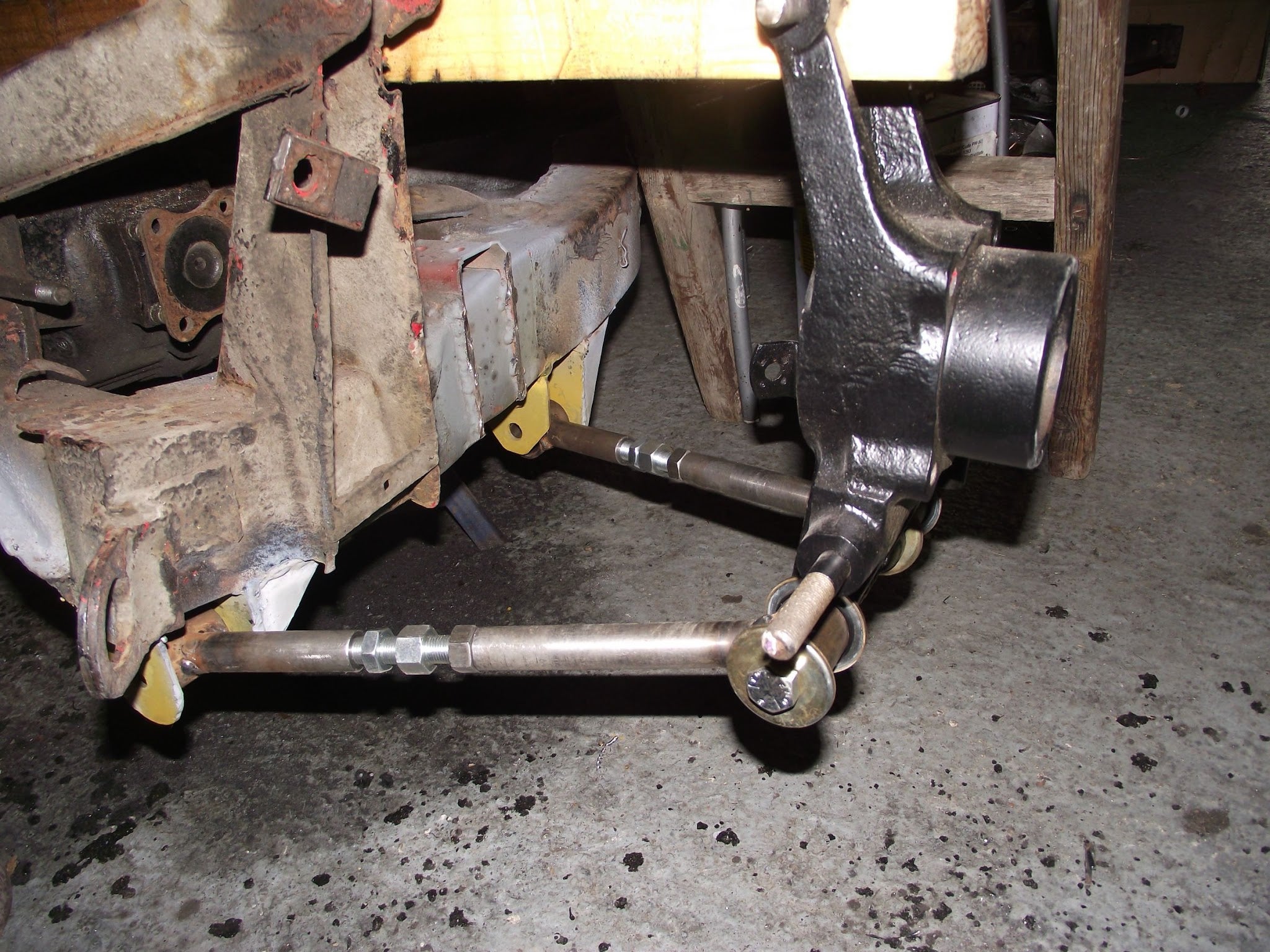

...iíve finally finished my lower wishbones!

Fully adjustable for camber and toe and as a happy coincidence significantly lighter than even the aftermarket alloy lower wishbone setup :)

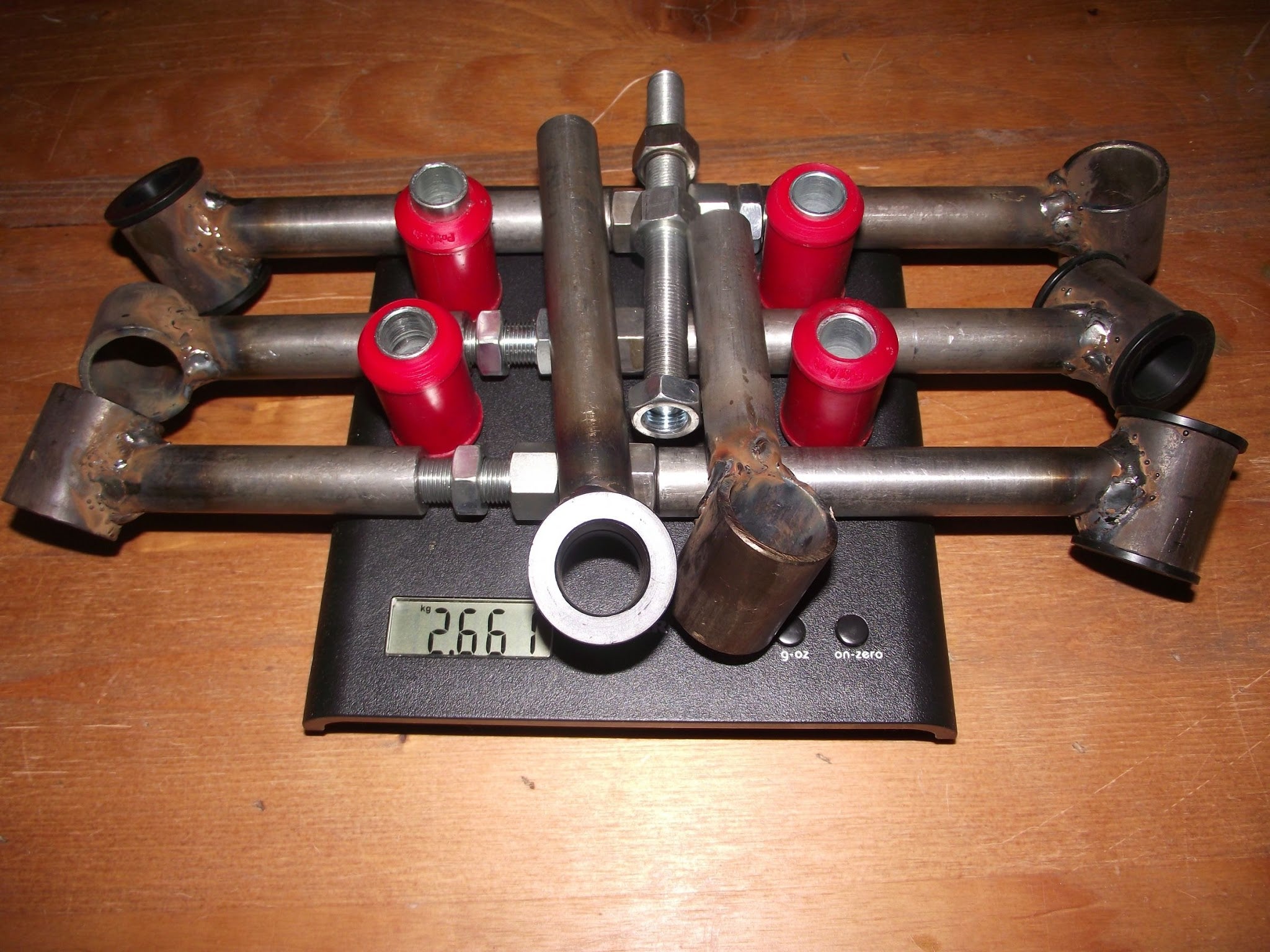

In order of weight we have:

Complete cast iron lower wishbone assembly: 6.788kg

Conplete alloy lower wishbone setup: 3.756kg

Complete tubular lower wishbone setup: 2.661kg

Iíve also managed to find a set of alloy 4-pot calipers and vented discs for £110 below retail in need of resealing (3.118 complete in case you were wondering, havenít weighted the vented discs yet though...)

Oh, and as you can see iíve been experimenting with an organic leaf spring in an effort to improve on the triumph one ;)

Leon711

> BiTurbo228 - Dr Frankenstein of Spitfires

Leon711

> BiTurbo228 - Dr Frankenstein of Spitfires

10/19/2015 at 06:43 |

|

Dat unsprung weight loss doe.

Sweet Trav

> BiTurbo228 - Dr Frankenstein of Spitfires

Sweet Trav

> BiTurbo228 - Dr Frankenstein of Spitfires

10/19/2015 at 07:11 |

|

Check this weld again. Please for my sanity. Smack the hell out of it with a slag hammer and make sure it is solid.

davedave1111

> BiTurbo228 - Dr Frankenstein of Spitfires

davedave1111

> BiTurbo228 - Dr Frankenstein of Spitfires

10/19/2015 at 07:15 |

|

Awesome, coming along nicely now. At this rate, should be done by Christmas... 2020 or so.

BiTurbo228 - Dr Frankenstein of Spitfires

> davedave1111

BiTurbo228 - Dr Frankenstein of Spitfires

> davedave1111

10/19/2015 at 08:15 |

|

With any luck yeah ;)

BiTurbo228 - Dr Frankenstein of Spitfires

> Sweet Trav

BiTurbo228 - Dr Frankenstein of Spitfires

> Sweet Trav

10/19/2015 at 08:17 |

|

All have been beaten up quite thoroughly to make sure theyíve stuck :)

That one has actually been welded over twice, hence the raised weld...

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

10/19/2015 at 09:15 |

|

A lot of the time, poly is an unnecessary step up in stiffness from rubber, but in this case... well, letís just say youíd have a lot of surprise toe-in change if you didnít. Given your new setup puts all the toe control on those bushings and the leaf at the top, and doesnít have any inherent reason/bracing for the lower arm trapezoid shape not to rack this way and that...

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

10/19/2015 at 09:59 |

|

Yeah you need as stiff of a setup here as possible :S fingers crossed there arenít any major issues.

If there are i think iíd need to add one or two arms reaching forwards but that would add weight and complexity...

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

10/19/2015 at 10:12 |

|

I know for a fact that some knobheads have used a Jag IRS without the stabilizer links, and with the third-member mounted solidly in place. Thatís far more questionable than anything youíre doing, but itís almost universally on trailer queens, and not anything that sees the track.

A stabilizer forward would cost you your gained kilo, but may end up being necessary. Canít really say, though - Iím not too worried about the shear force on your through-bolt with a Spitís modest weight requirements, and that seems the point of greatest difficulty. I should note, though, that your torsion resistance is pretty much all down to the spring, so donít expect any miracles of your rear brakes. A little caster change under braking and a little under accel wouldnít be surprising. :X

crowmolly

> BiTurbo228 - Dr Frankenstein of Spitfires

crowmolly

> BiTurbo228 - Dr Frankenstein of Spitfires

10/19/2015 at 10:17 |

|

Drill and tap them for a zerk fitting, otherwise the poly will bind.

RamblinRover Luxury-Yacht

> crowmolly

RamblinRover Luxury-Yacht

> crowmolly

10/19/2015 at 10:34 |

|

Very much this.

crowmolly

> BiTurbo228 - Dr Frankenstein of Spitfires

crowmolly

> BiTurbo228 - Dr Frankenstein of Spitfires

10/19/2015 at 10:35 |

|

What does the penetration look like on the inside of the tube? I swear Iím not trying to be a prick.

BiTurbo228 - Dr Frankenstein of Spitfires

> crowmolly

BiTurbo228 - Dr Frankenstein of Spitfires

> crowmolly

10/19/2015 at 11:39 |

|

The polybushes are meant to be stationary in the eyes, and suspension movement is done by flex in the bush :)

BiTurbo228 - Dr Frankenstein of Spitfires

> crowmolly

BiTurbo228 - Dr Frankenstein of Spitfires

> crowmolly

10/19/2015 at 11:41 |

|

No by all means :) looks good, nice even line of discolouration where iíve welded but not hot enough to cause a bubble.

crowmolly

> BiTurbo228 - Dr Frankenstein of Spitfires

crowmolly

> BiTurbo228 - Dr Frankenstein of Spitfires

10/19/2015 at 11:50 |

|

Not sure I follow you. What material touches the steel mount points?

BiTurbo228 - Dr Frankenstein of Spitfires

> crowmolly

BiTurbo228 - Dr Frankenstein of Spitfires

> crowmolly

10/19/2015 at 14:40 |

|

The polybushes are pressed into the eyes (just bush against tube) then thereís a metal tube down the centre that will be clamped up inside the chassis brackets (the reason itís braced on one side but not the other...).

crowmolly

> BiTurbo228 - Dr Frankenstein of Spitfires

crowmolly

> BiTurbo228 - Dr Frankenstein of Spitfires

10/19/2015 at 14:43 |

|

Like these?

If so, yeah, you need grease.

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

10/19/2015 at 14:55 |

|

Yeah I donít expect it to be the last word in stability, but itís a massive improvement over the built-in changes of the standard suspension...

Not a clever idea there with the Jag IRS. Really not clever.

Howís yours coming btw?

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

10/19/2015 at 15:10 |

|

I know they flex or slip in theory, but they do best when greased. Otherwise, partial seizing to the steel through-shaft and squeaking cause no end of trouble. Itís just how poly bushes are. Thatís actually covered in your suspension design book, if Iím not mistaken.

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

10/19/2015 at 15:14 |

|

Well, the suspensionís pretty much all set in the rear, save for the stabilizing links. I just recently got a set of A-arm bushings for a GM van to go on their front ends (need radial flex capability as well as up/down rotation, and Iíll be making the links themselves from some DOM tubing Iím ordering this week through work. In the meantime , Iíve been working on the fit of those body parts that arenít supposed to work together, and Iíve pulled the roof skin and back of the cab off.

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

10/19/2015 at 15:51 |

|

Another note on the dolt with the Jag suspension on his Chevy, mostly trivia: Heís dropped to a single spring/shock per side because the XJS rear he started with was too heavily sprung, not a surprise. His spring rate, however, would almost certainly have been alright if heíd spent the mere $160 in springs and an afternoon in the garage to swap for Series I E pieces. Entirely new springs, with about the correct response. Nope.

Related note: the swap to XKE springs is something I myself will be doing, when I get a chance.

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

10/20/2015 at 17:02 |

|

Nice :) glad to see youíre making progress. Iíve just made a start on notching the chassis to provide clearance for the speedo angle-drive which is one of the last few modifications to the chassis that needs to be done :)

Next up after that is a diff rebuild with a quaife lsd :)

BiTurbo228 - Dr Frankenstein of Spitfires

> crowmolly

BiTurbo228 - Dr Frankenstein of Spitfires

> crowmolly

10/21/2015 at 02:38 |

|

Ah yeah, pretty much that. Iíll grab some as soon as I can :)

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

10/21/2015 at 02:39 |

|

Really must read that...

crowmolly

> BiTurbo228 - Dr Frankenstein of Spitfires

crowmolly

> BiTurbo228 - Dr Frankenstein of Spitfires

10/21/2015 at 10:11 |

|

Is it the Herb Adams book?